Onsite Generators

SICGILSOL’s on-site nitrogen generator solutions offer a continuous and secure supply of nitrogen gas which can otherwise be expensive and troublesome. The ideal solution lies in a range of proven gas generation systems developed by SOL, Italy’s R&D team, which is based upon 3 important factors.

1) Flow Rate

2) Purity

3) Application

SICGILSOL proposes to use

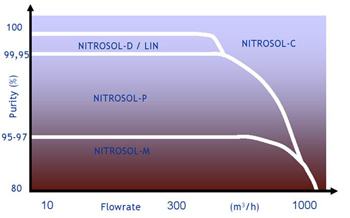

NitroSOL – M

Membrane Gas generators for applications that require lower purity from 93%-98%.

The concept of gas separation by hollow fiber membranes is simple. A small hollow tube allows unwanted gases such as oxygen and water vapor to permeate through its walls while nitrogen is retained for use in the application.

NitroSOL – P

PSA Multibank Models for flow rates between 1-200 Nm3/hr and purity in the range of

98% -99.99% Nitrogen. The generators contain twin chambers of Carbon Molecular Sieve ( CMS ), a material which removes oxygen and traces gases from compressed air by molecular adsorption, allowing nitrogen to pass through as the product gas.

NitroSOL – CX

Cryogenic Distillation for flow rates more than 150 Nm3/hr and purity greater than or equal to 99.99%. Compressed air is cooled down to cryogenic temperatures and fed into a distillation column system. The air is distilled to produce the required nitrogen gas. Returning product streams are used to cool the compressed air feed. The gaseous product is then delivered to the customer.

Industries Served:

Nitrogen generators are the most convenient and optimal solution for

- Pharmaceutical companies for their purging/blanketing needs

- Food processing and packaging industries for their Modified Atmosphere Packaging

- Chemical/Petrochemical industries for purging or other processes

- Other manufacturing industries

The Italian advantage:

SOL, the Italian joint venture partner has helped companies from various industries – iron and steel, chemicals, food processing, pharmaceutical set up on site production systems for their nitrogen needs on a long term rental facility basis.

NitroSOL for Pharmaceutical Industries

Our range of Pharma Grade gases produced from our generators is fully compliant with European Pharmacopoeia and GMP part II to provide certification, traceability and complete peace of mind.

FAQ'S

Pharma grade gases are produced in accordance with GMP part 2, detailing production and analytical process requirements as well as documentation. Their specifications are compliant with European Pharmacopoeia. Standard grade gases are produced following ISO 9001 procedures against internal quality specifications.

Most pharmaceutical companies are requesting higher purity specifications than specified by the corresponding monograph of the European Pharmacopoeia as they want to be absolutely sure that no impurities from the gas are entering the API. SICGILSOL has therefore chosen to supply you a better quality product within the requirements of EP. Thanks to the guarantee that we provide, your supplier qualification process will be reduced and your in house controls can be reduced.

Yes. SICGILSOL provides a Certificate of Analysis which details analytical results and methods used, compliant with the monographs of the European Pharmacopoeia.

NitroSOL for Food industries – Modified Atmosphere Packaging

Modified Atmosphere Packaging is the process of replacing the air with a mixture of gases ( mostly nitrogen or nitrogen-carbon di oxide mixtures ) in order to improve the

- Shelf Life

- Retain freshness and aroma of the food

- Better visual appeal

Sample table of different products and how MAP can improve the shelf life

| Raw Red Meat | 2 4 days | 5 8 days |

| Raw light Poultry | 4 - 7 days | 16 - 21 days |

| Raw dark Poultry | 3 - 5 days | 7 - 11 days |

| Sausages | 2 - 4 days | 2 - 5 Weeks |

| Sliced cooked meat | 2 - 4 days | 2 - 5 Weeks |

| Raw fish | 2 - 3 days | 5- 9 days |

| Cooked fish | 2 - 4 days | 3 - 4 Weeks |

| Hard cheese | 2 - 3 Weeks | 4 - 10 Weeks |

| Soft Cheese | 2 - 3 Weeks | 4 - 10 Weeks |

| Cakes | Several weeks | Up to one year |

| Bread | Some days | 2 Weeks |

| Pre-baked bread | 5 days | 20 days |

| Fresh cut salad mix | 2 -5 days | 5 -10 days |

| Fresh pasta | 1 - 2 Weeks | 3 - 4 Weeks |

| Pizza | 7 -10 days | 2 - 4 Weeks |

| Pies | 3 - 5 days | 2 - 3 Weeks |

| Sandwiches | 2 - 3 days | 7 - 10 Weeks |

| Ready meals | 2 - 5 days | 7 - 20 days |

| Dried foods | 4 - 8 months | 1 - 2 Years |

- Back up liquid nitrogen supply for peak flow requirements

- Constant purity and on-site control

- Reduced paper work and processing time

Nitrogen Cost

Nitrogen purity and flow rate can affect nitrogen cost. Higher purity comes at a price but higher volume generally reduces the unit cost of nitrogen. For maximum savings, use a nitrogen purity no higher than the application requires.

Reliable Back Up Supply

All our nitrogen generators are accompanied with liquid nitrogen back up tank supply. It provides the consumer with peace of mind whenever there are maintenance down times, power cuts or unforeseeable events. Our regional logistics network with centrally managed India wide coordination, combined with superior production planning, ensures that every single customer receives a reliable supply of technical gases from SICGILSOL, even during planned and unplanned downtimes.